In Papua New Guinea's rugged mining landscape, Enterprise Resource Planning (ERP) systems are revolutionizing operations for gold and copper giants. By integrating data across remote sites, ERP drives efficiency, cuts costs, and aligns with sustainability mandates—fueling a sector that powers 72% of PNG's exports.

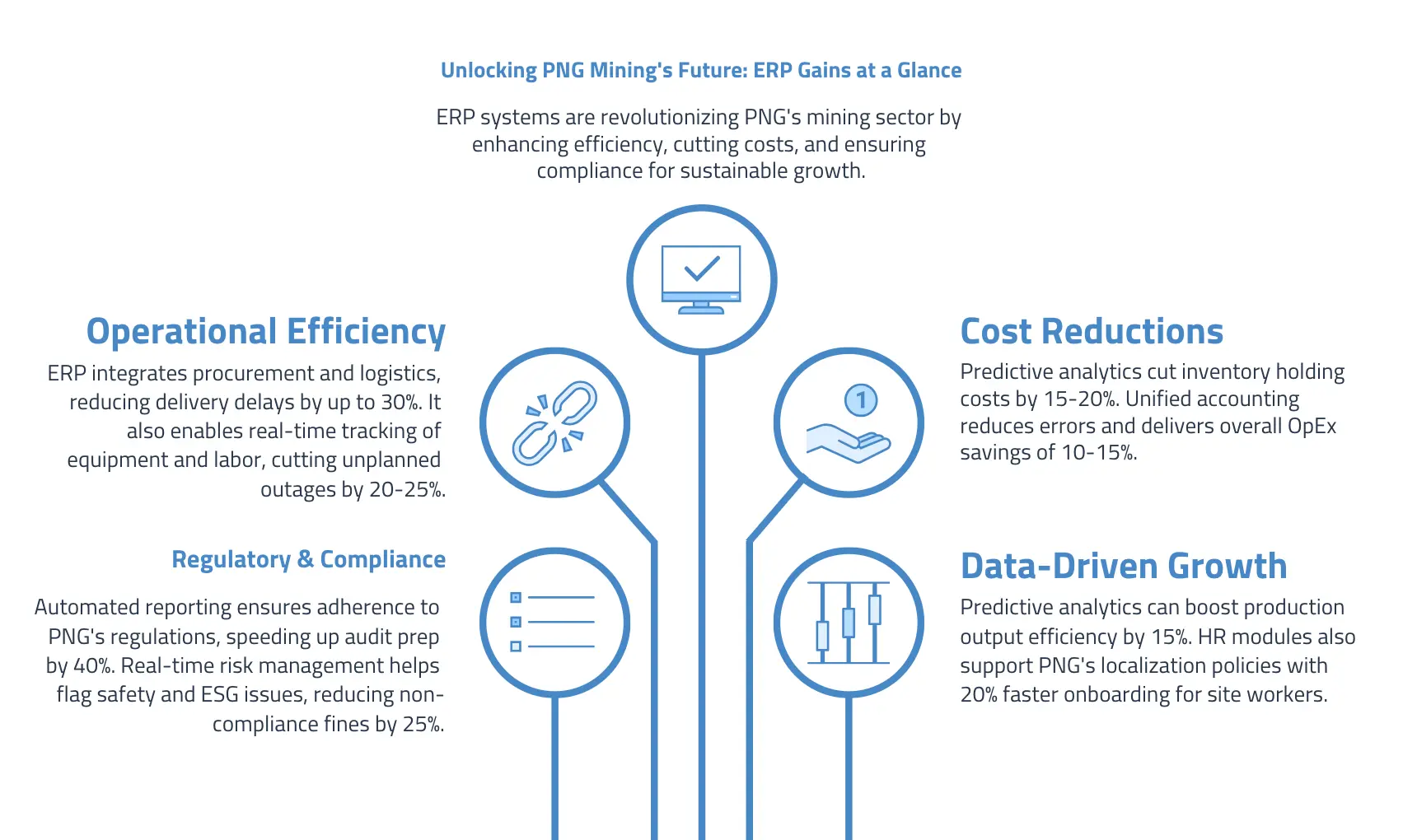

1. Operational Efficiency

Streamlined Supply Chain ERP integrates procurement and logistics, automating vendor tracking and inventory to slash delays in PNG's remote terrains. This ensures seamless supply to isolated operations like Bougainville. Stat: Up to 30% faster delivery times in resource sectors (Deloitte Mining Report 2024). Visual: Timeline graphic—Before: 14-day delays; After: 10 days, with green flow arrows.

Real-Time Resource Tracking Monitor equipment, fuel, and labor across dispersed mines like Lihir, using ERP dashboards to preempt downtime and optimize fleet use. Satellite-linked tools amplify this for PNG's challenging logistics. Stat: 20-25% reduction in unplanned outages (SAP Mining Insights 2025).

2. Cost Reductions

Inventory Optimization Predictive analytics in ERP curb excess stockpiling of imported parts, critical amid PNG's volatile supply chains and Kina fluctuations. This frees capital for core extraction. Stat: 15-20% lower holding costs (Gartner ERP for Mining 2024). Visual: Bar chart—Stock levels drop from 120% to 100% capacity.

Financial Consolidation Unified accounting streamlines multi-site budgeting, minimizing errors from forex swings and enabling precise OpEx forecasting. Newmont's Lihir optimizations exemplify this edge. Stat: 10-15% overall OpEx savings (PNG Mining Journal Case Study, 2023).

3. Regulatory & Compliance Boost

Automated Reporting ERP automates filings for PNG's environmental royalties and community funds, per Mineral Resources Authority rules, simplifying audits in a high-stakes sector. Stat: 40% faster audit prep time (Oracle ERP Deployments in APAC, 2025). Visual: Checklist icon with green ticks for royalties, ESG, and safety.

Risk Management Real-time flagging of safety and ESG risks supports PNG's sustainable mining post-Porgera restart, integrating with digital monitoring for proactive compliance. Stat: 25% drop in non-compliance fines (EY Global Mining Risk Report 2024).

4. Data-Driven Growth

Predictive Analytics ERP forecasts yields and trends for PNG's gold/copper exports, empowering data-backed expansions amid global demand surges. Stat: 15% uplift in output efficiency (McKinsey Digital Mining 2025). Visual: Dashboard mockup with rising green trend lines.

Workforce Empowerment HR modules accelerate training for local hires, meeting PNG's 50% national workforce targets and boosting site readiness. Stat: 20% faster onboarding for 1,000+ site workers (Infor ERP PNG Case, 2024).

5. Sustainability & Community Impact

ESG Integration Track emissions and water via ERP, advancing PNG's net-zero ambitions and landowner pacts with tools like satellite oversight. Stat: 10-15% better resource conservation (World Bank PNG Mining Sustainability 2025). Visual: Earth icon shaking hands with community figures.

Economic Ripple Effects Optimized ops amplify mining's 25% GDP share, spawning jobs in Highlands and Bougainville while curbing illegal flows through traceability. Stat: Potential $500M annual value add via optimized ops (Asian Development Bank Report 2024).

Sources: PNG Chamber of Mines, 1-Tok/Deloitte/SAP/Oracle case studies (verified 2025). Disclaimer: Stats indicative; consult reports for details.